The Process of Applying Spray Foam: What You Required to Know

Spray Foam: The Ultimate Service for Air Sealing and Insulation

Spray foam insulation has emerged as a leading remedy for reliable air securing and thermal insulation, supplying an one-of-a-kind mix of residential properties that establish it apart from standard methods. Understanding the full extent of its advantages, setup processes, and comparisons with various other insulation kinds is crucial for making educated choices.

What Is Spray Foam?

Spray foam is a functional insulation product that combines the principles of air securing and thermal resistance to boost power performance in structures. Composed primarily of polyurethane or various other similar substances, spray foam is applied as a liquid that increases upon contact with surface areas, developing a solid, continuous layer of insulation. This one-of-a-kind residential or commercial property allows it to load spaces, cracks, and gaps that conventional insulation products might neglect, providing a premium air seal.

There are two major kinds of spray foam: open-cell and closed-cell. Open-cell spray foam is lighter and much more adaptable, offering superb noise absorption and a reduced R-value per inch - Spray Foam. In contrast, closed-cell spray foam is denser, giving a higher R-value, dampness resistance, and added architectural stability to constructing components

The application procedure usually involves specific equipment, making sure a smooth application that follows different substrates, including wood, steel, and concrete. This flexibility makes spray foam appropriate for both brand-new buildings and retrofitting existing frameworks. Its ability to create a closed obstacle considerably adds to reducing energy intake and enhancing interior air quality, thus making it a recommended choice among contractors and house owners alike.

Benefits of Spray Foam Insulation

Among one of the most significant advantages of spray foam insulation is its outstanding capability to create a constant air obstacle, which effectively minimizes energy loss. Unlike standard insulation products, spray foam increases to load gaps and cracks, guaranteeing that air leakage is significantly decreased. This characteristic not only enhances power performance but additionally results in reduce energy costs with time.

In addition, spray foam insulation supplies premium thermal resistance, adding to an extra steady indoor atmosphere. Its high R-value per inch permits effective insulation in constrained spaces, making it excellent for attics, wall surfaces, and crawl areas. The moisture-resistant buildings of spray foam help protect against mold and mildew and mildew development, advertising much healthier living conditions.

Another crucial benefit of spray foam insulation is its sound-dampening qualities (Spray Foam). It effectively decreases noise transmission between areas, developing a quieter and a lot more comfortable home environment. The durability of spray foam additionally stands apart, as it does not sag or resolve gradually, maintaining its efficiency throughout its lifespan

Exactly How Spray Foam Functions

Comprehending just how spray foam insulation works is vital for valuing its efficiency in air securing and thermal resistance. Spray foam insulation consists of 2 key elements: isocyanate and polyol resin. When these parts are blended, they undertake a chemical reaction that triggers the product to broaden swiftly, producing a thick foam that loads gaps, tooth cavities, and cracks.

As the foam broadens, it abides by surfaces, creating an airtight seal that considerably reduces air infiltration. This particular makes spray foam insulation very reliable at preventing drafts and wetness infiltration, which can result in power loss and damages over time. In addition, the closed-cell version of spray foam provides premium thermal resistance because of its rigid structure, properly minimizing warm transfer.

The unique residential properties of spray foam allow it to satisfy uneven surface areas, ensuring thorough protection and a seamless barrier. Therefore, spray foam insulation not only improves energy effectiveness however also adds to enhanced indoor air high quality by reducing the build-up of contaminants and allergens. Inevitably, comprehending the technicians behind spray foam highlights its duty as a superior choice for insulation and air sealing in both property and industrial applications.

Setup Process Review

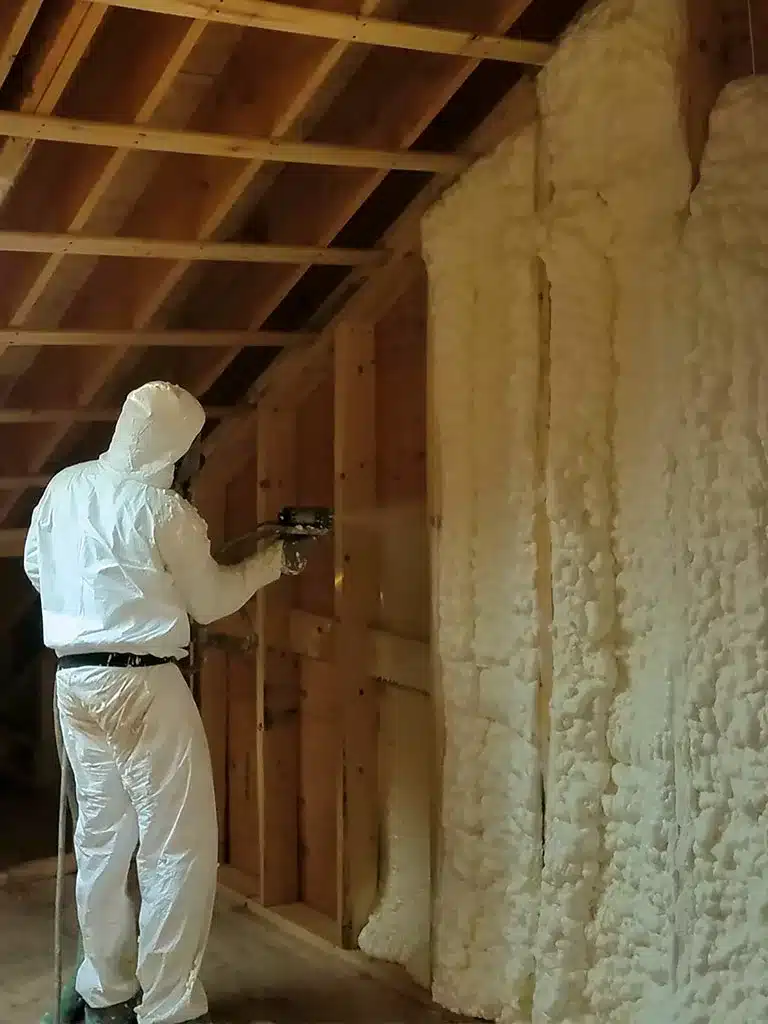

Prior to installment, the room should be effectively cleaned up and prepped, making straight from the source certain that surfaces are devoid of dirt, particles, and wetness. This step is critical because contaminants can jeopardize bond and general efficiency. When the area is prepared, the application entails mixing both parts of the spray foam, which increases upon contact and loads gaps efficiently.

Trained experts ought to carry out the installment, making use of customized devices to ensure consistent protection and optimal density. Safety and security safety measures, consisting of using safety equipment and making certain proper ventilation, are vital throughout this procedure. After application, the foam normally remedies rapidly, forming a solid barrier that improves power effectiveness.

Contrasting Spray Foam to Typical Insulation

When evaluating insulation options, spray foam insulation stands out in comparison to standard products such as fiberglass and cellulose. Unlike fiberglass and cellulose, which can enable air seepage, spray foam increases upon application, filling holes and voids to produce an airtight seal.

Additionally, spray foam offers a greater R-value per inch than standard insulation kinds, using more efficient thermal resistance in a thinner account. This characteristic is especially beneficial in rooms with restricted cavity deepness. Spray foam is immune to wetness and mold growth, which can be a substantial worry with cellulose and fiberglass, specifically in humid atmospheres.

Nonetheless, spray foam insulation normally lugs a greater ahead of time cost than its conventional counterparts. Homeowners must weigh this initial investment versus lasting power financial savings and efficiency benefits. Inevitably, while both insulation types offer their purpose, spray foam arises as an advanced solution for modern insulation needs, especially in regards to air sealing and thermal visit this web-site effectiveness.

Verdict

In recap, spray foam insulation represents a very efficient remedy for accomplishing optimal air securing and article source thermal resistance. Its special residential properties, consisting of moisture resistance and noise dampening, make it suitable for different applications in both new constructions and retrofitting jobs (Spray Foam). Although the first costs might be higher contrasted to standard insulation materials, the long-term benefits, such as significant power cost savings and improved indoor air top quality, validate the investment and highlight its worth in contemporary structure practices.

Spray foam insulation has arised as a leading option for reliable air securing and thermal insulation, supplying an unique mix of residential properties that set it apart from typical methods.Spray foam is a flexible insulation material that incorporates the concepts of air sealing and thermal resistance to boost energy effectiveness in buildings.When examining insulation choices, spray foam insulation stands out in comparison to standard products such as fiberglass and cellulose. Inevitably, while both insulation kinds offer their purpose, spray foam arises as an extra innovative service for modern-day insulation needs, especially in terms of air securing and thermal effectiveness.

In recap, spray foam insulation represents a highly efficient remedy for attaining optimal air sealing and thermal resistance.